Paint booths are an essential element in any production process where coatings or glues are applied. Painting outdoors or without any filtration measures is a thing of the past, as current regulations on emissions into the atmosphere are becoming more stringent. For this reason, the booths for the application of liquid paints, presented in its two main currents: water curtain and dry filter, have become the main solution for those producers who seek to care for the environment and comply with the applicable regulations.

Water curtain booths

As its name indicates, these booths use a curtain of water to capture the pulverized paint particles, which later fall into a tank with the rest of the water and the chemicals needed for processing.

Water curtain huts have evolved little over time and one of the complications that characterizes them is the management of wastewater which, despite the chemicals applied, is inevitably generated after a certain period. Since it is impossible to dispose of it through the drainage networks due to its toxic components, the water turns into a sludge that hinders the work of the water recirculation pumps and eventually causes them to burn; in addition to causing the irrigation nozzles or distribution holes to become clogged. Regarding the chemicals that are mentioned to process the captured paint and maintain the water conditions, it is relevant to mention that these must be applied by qualified personnel, which sometimes represents a difficulty for the company.

Dry filter houses

En Wirbel nos hemos enfocado en la segunda categoría de casetas y hemos dado un especial impulso al uso de los filtros secos, que surgieron en los sesentas con los llamados “paint arrestors” y han evolucionado hasta las múltiples opciones que hoy en día existen, convirtiéndose en una solución real para la retención de pintura con un fácil manejo y rápido cambio.

Our new line of “DuoSec” paint booths is manufactured under quality and practicality standards that guarantee low-cost and easy maintenance. For this reason, Wirbel includes the “Andreae” product line as an essential component in its booths, a leading Swiss brand in the international market whose design provides greater filtration efficiency due to its inertial separation system.

The “DuoSec” booth is also equipped with a powerful axial extractor that provides us with a large volume of air at a very low energy cost, made with a non-sparking cast aluminum blade and a high-efficiency three-phase electric motor with transmission by means of pulleys. and bands. In addition, they have a perimeter base, as well as an internal structure to support the extractor, which provide excellent rigidity to the whole.

More posts

La Industria vs. El Medio Ambiente

MANTENIMIENTO DE EXTRACTORES INDUSTRIALES

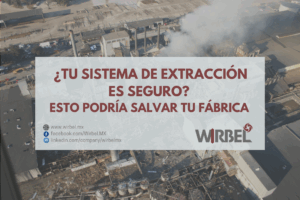

¿TU SISTEMA DE EXTRACCIÓN ES SEGURO? ESTO PODRÍA SALVAR TU FÁBRICA